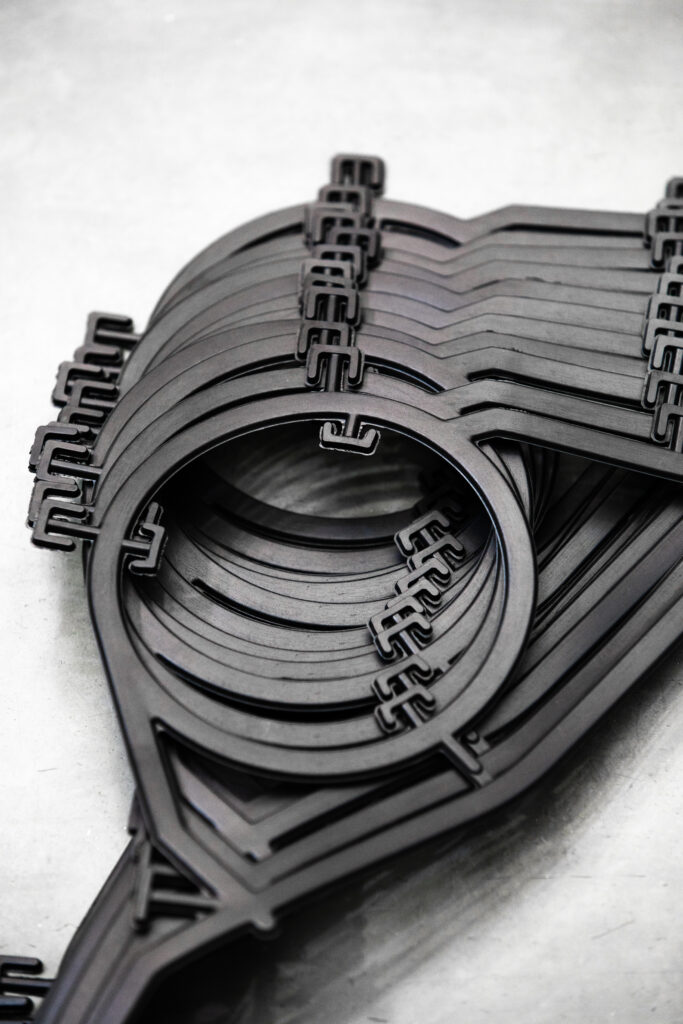

PHEwtur offers one of the wide range of equivalent gaskets for Kelvion plate heat exchangers.

CT193

FA157

FA159

FA161

FA184

FA192

LWC100T

LWC150S

N40

NT80M

NT100M

NT100T

NT100X

NT150L

NT150S

NT250L

NT250S

NT350L

NT350M

NT350S

NT50M

NT50T

NT50X

NT25M

NX25M

NX150X

VT04P

VT10

VT20

VT20P

VT40

VT40

MTU

VT40P

VT40P/M

VT405P

VT80

VT80 FULL END

VT80M

VT80P

VT130F

VT130K

VT180M

VT402

VT805

VT1306

VT1309

VT2508

Kelvion, formerly known as GEA Heat Exchangers, was originally founded in 1920 by Otto Happel. The name “Kelvion” was chosen as a tribute to Lord Kelvin, whose work in thermodynamics led to the creation of the absolute temperature unit, the kelvin. In 2014, GEA sold its Heat Exchanger division to the Triton investment group, and in 2015, the Kelvion brand was officially launched.

Today, Kelvion is recognized worldwide for its deep technical knowledge and its focus on energy-efficient, cost-effective thermal technologies. While their plate heat exchangers are widely used in food processing—particularly in the beverage industry—they are also essential in various other fields such as chemical processing, pharmaceuticals, gas handling, and any industry requiring heat exchange on wetted surfaces.

Kelvion stands out as a global leader in high-efficiency, low-energy thermal solutions, offering strong value to customers through a broad product portfolio. This includes steam boilers, waste heat recovery systems, industrial water heaters, and chillers. The company also manufactures a full range of tubular and plate heat exchangers—brazed, welded, and gasketed.

Among Kelvion’s plate heat exchangers, the ECOFLEX range is particularly noteworthy. It consists of five product lines tailored to different needs: NT, GG, FREE FLOW, CONCITHERM, and SAFETYTHERM.

SAFETYTHERM Series: As the name implies, this range prioritizes safety. The dual-plate design ensures that, in case of leakage, fluids will not mix. Any leak is directed between the plates, avoiding cross-contamination.

PHEwtur offers an extensive selection of compatible gaskets designed to match the original performance specifications of Kelvion plate heat exchangers. These equivalent gaskets meet OEM standards but are available at a more competitive price.

What truly defines the quality of a gasket isn’t just the brand—it’s the raw material behind it. PHEwtur focuses on premium-grade European-sourced elastomers, ensuring durability and chemical resistance across a wide range of applications.

As a global expert in elastomer gasket production and supply, PHEwtur delivers high-quality sealing solutions that fully comply with Kelvion’s requirements. Each gasket undergoes strict quality control and is validated by technical specialists for optimal performance.

Want to learn more? Contact us and our team will be happy to assist you.