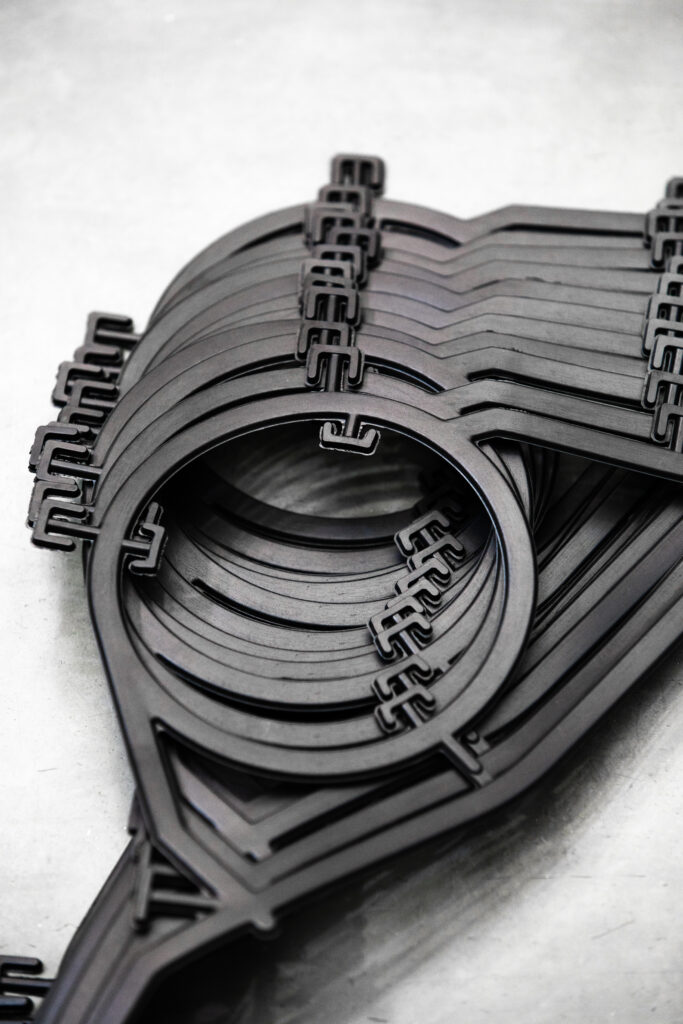

PHEwtur offers one of the wide range of equivalent gaskets for Polaris plate heat exchangers.

S8

S15

S20

S30

S38

S39

S50

S65

S100

S120

Polaris plate heat exchangers, based in Louisville, Kentucky, has established itself as a leading force in the design and manufacturing of plate heat exchangers. Since the begining, Polaris has been dedicated to delivering efficient and reliable thermal solutions for a wide range of industries, including HVAC, food and beverage, marine, oil and gas, and more.

The company stands out thanks to its unwavering focus on quality, energy efficiency, and durability. With deep technical expertise and a keen understanding of each sector’s unique requirements, Polaris has developed a complete line of heat exchangers capable of meeting the most demanding thermal challenges.

Polaris offers a comprehensive range of heat exchangers designed for diverse applications:

Polaris heat exchangers are used in many industries:

In HVAC, for heating, cooling, and energy recovery systems in residential and commercial buildings.

In food and beverage, for processes such as pasteurization, cooling, and heating.

In marine, for engine cooling and onboard freshwater generation.

In oil and gas, for heat recovery and fluid treatment.

In cogeneration, to maximize the efficiency of simultaneous electricity and heat production.

At PHEwtur we are thrilled to manufacture high-quality equivalent gaskets for Polaris plate heat exchangers, offering the identical standards as original equipment manufacturers (OEM) gaskets.

Choosing a smaller company is choosing a fast and personnalize customers service. How can we recognize a high-quality gasket ? By looking the right raw material. At PHEwtur, only European-sourced elastomers are used, ensuring efficiency and durability. Our gaskets have the same warranty as the OEM (1 year).

As a recognized global expert in elastomer gasket manufacturing, PHEwtur provides a broad range of gaskets following Bell&Gossett’s specifications, fully compliant with international quality benchmarks.

All PHEwtur gaskets are subject to rigorous testing by experienced technical teams.

Interested in learning more? Contact us and let’s talk about the right gasket for your system.