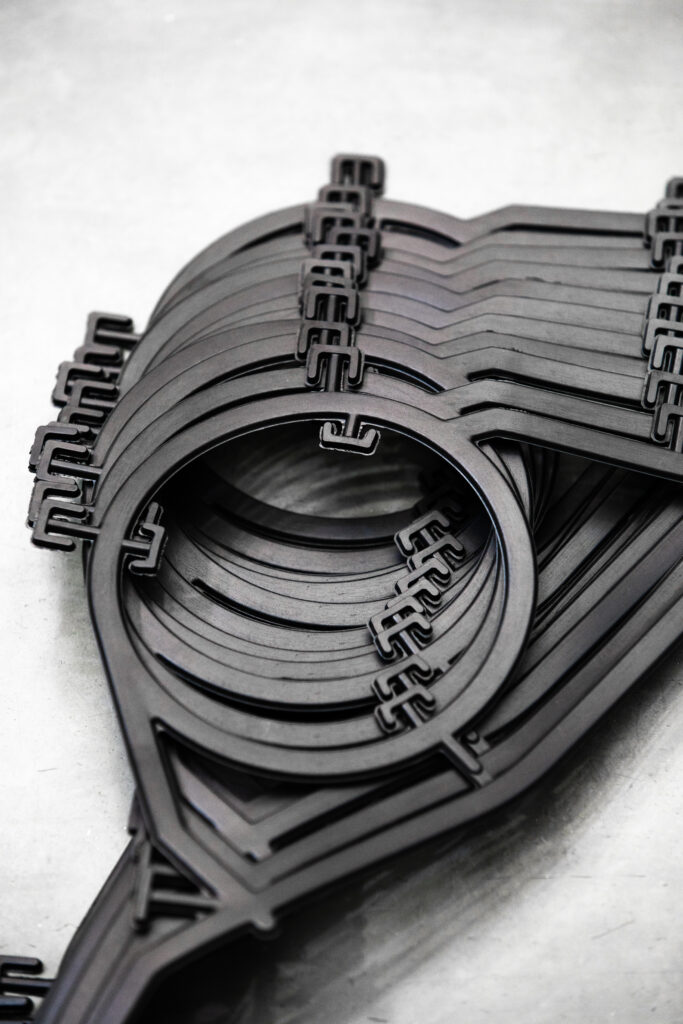

PHEwtur offers one of the wide range of equivalent gaskets for SPX plate heat exchangers.

A055

A085

B063L

B063S

B110L

B110S

B134L

B134S

B158L

B158S

B205L

B205S

D37

ER5

FFPE

FFPE NARROW

H12

H17

H17 DUOSAFETY

HMB

HX

J060

J092

J107

QD055

QD080

QE030

QE055

QE080

RFFPE

R5 (New design)

R6

R8AH

R8GI

R10

R14

R23

R40

R55

R86

R89

R106

R145

R235

R405

S190

SD9

SR1

SR2

J185

JUNIOR

JUNIOR EVAP

K34

K55

K71

K71 DUOSAFETY

LR9AL

LR9GL

LR9GN

M60

M92

M107

M185

N25

N35

N35 DUOSAFETY

N50

NR5

O034 ES

O050 ES

P105

P105 PARACLIP

P190

QD030

SR3

SR9

SR14AD

SR14AG

SR14AH

SR14AN

SR14AP

SR14GD

SR14PP

SR15PE

SR23AO

SR23VO

SR6AA

SR6AG

SR6GH

SR6GL

SU6GL

T4

TR1

TR9AL

TR9AV

TR9GN

U2

WHX

The origins of SPX date back to 1912 with the founding of Piston Ring Company in Detroit, Michigan. The company quickly gained a reputation for quality as it began supplying components to major automobile manufacturers.

In 1931, Piston Ring acquired Accuralite and was renamed Sealed Power Corporation, expanding its expertise in manufacturing components for military and automotive applications. By the mid-20th century, the company’s parts were used as original equipment in 80% of vehicles produced in the United States and were sold in over 40 countries.

During the 1980s and 1990s, Sealed Power Corporation began diversifying its operations by acquiring other companies in the replacement parts and industrial equipment sectors. This transformation led to the formation of SPX Corporation.

In the early 2000s, SPX invested heavily in expanding its capabilities in industrial technology, with a focus on food and beverage processing, power and energy, and specialized engineered solutions. SPX has since become a global leader in the design and manufacturing of thermal solutions, including heat exchangers.

SPX® designs and manufactures a wide range of heat exchangers for industrial applications, known for their high performance, durability, and innovation. Key types of heat exchangers offered include:

Plate Heat Exchangers

Available in various sizes, these exchangers are ideal for applications requiring large heat transfer surface areas in compact designs. They offer excellent thermal efficiency and are widely used in HVAC, food processing, and industrial utilities.

Tubular Heat Exchangers

Designed for high-capacity thermal applications, SPX tubular exchangers are used in industries such as power generation, chemical processing, and petrochemicals.

Shell and Tube Heat Exchangers

These are ideal for applications with demanding thermal requirements, providing high heat transfer rates and mechanical strength. Commonly used in oil & gas, energy production, and heavy industry.

Energy Recovery Heat Exchangers

These exchangers capture and reuse thermal energy from industrial processes, improving overall efficiency and reducing energy costs. They are frequently used in power plants and process industries.

Spiral Heat Exchangers

Designed for space-constrained environments, SPX spiral heat exchangers deliver high heat transfer efficiency and are used in compact industrial systems across several sectors.

SPX also provides a full suite of replacement parts, accessories, and support services to maintain optimal equipment performance and extend product lifespan.

PHEwtur has specialized in the manufacture and supply of high-quality equivalent gaskets for all major plate heat exchanger brands, including SPX.

Our SPX-compatible gaskets are manufactured to the highest quality standards and meet or exceed the performance of OEM parts. We use advanced elastomers such as Nitrile (NBR), EPDM, Silicone, and FKM (Viton®) to ensure excellent resistance to chemicals, heat, and pressure.

Our expert team ensures that every gasket is produced with precision and reliability. All our equivalent gaskets are backed by a one-year performance guarantee, giving you peace of mind and operational continuity.

Want to learn more? Contact us and our team will be happy to assist you.