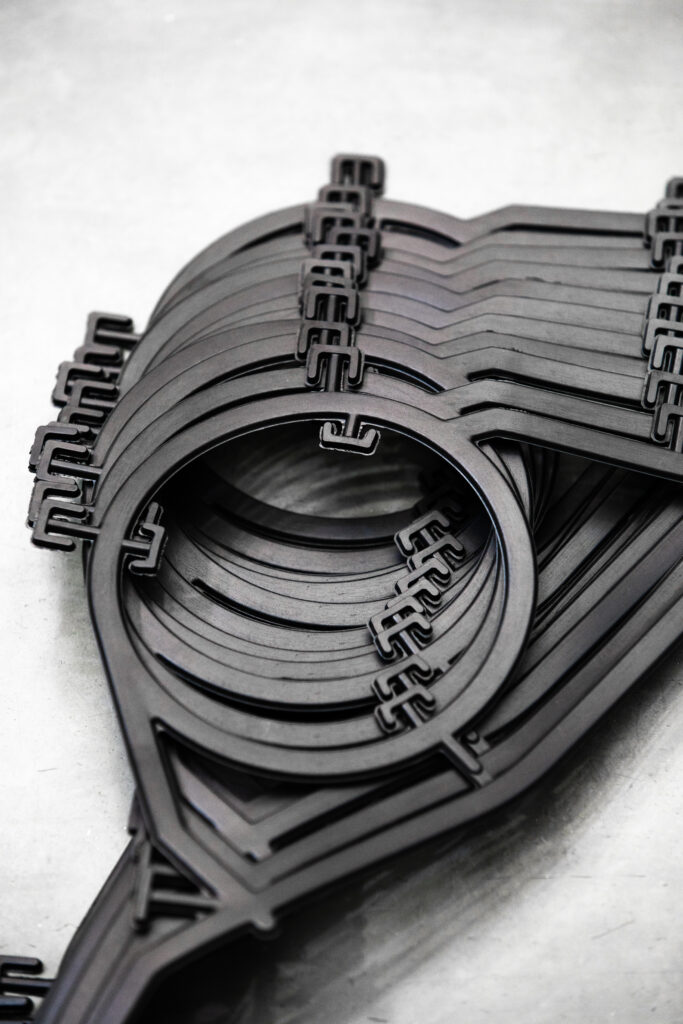

PHEwtur offers one of the wide range of equivalent gaskets for Tranter plate heat exchangers.

CT193

FA157

FA159

FA161

FA184

FA192

LWC100T

LWC150S

N40

NT80M

NT100M

NT100T

NT100X

NT150L

NT150S

NT250L

NT250S

NT350L

NT350M

NT350S

NT50M

NT50T

NT50X

NT25M

NX25M

NX150X

VT04P

VT10

VT20

VT20P

VT40

VT40

MTU

VT40P

VT40P/M

VT405P

VT80

VT80 FULL END

VT80M

VT80P

VT130F

VT130K

VT180M

VT402

VT805

VT1306

VT1309

VT2508

Founded in 1937 by R.E. Tranter, the company began its journey by introducing a groundbreaking design for gasketed plate heat exchangers that revolutionized the industry. The new design offered better thermal efficiency and easier maintenance compared to existing solutions, quickly establishing Tranter as a trusted name in the chemical sector.

As the demand for efficient heat transfer systems grew, Tranter expanded rapidly, opening production and service sites across the United States and Europe to serve an evolving client base.

In the 1960s, the company turned its attention to emerging sectors such as nuclear energy and offshore oil and gas. This focus led to the development of more specialized exchangers, including welded plate and spiral types—both suited for demanding operating environments.

By the 1990s, Tranter had firmly established itself as an innovator. New product lines featured compact designs with enhanced thermal efficiency and streamlined maintenance. The company also widened its global reach, setting up operations across Asia, Latin America, and the Middle East.

Today, Tranter continues to lead in heat exchanger technology, with a presence in more than 50 countries and a portfolio that adapts to the changing needs of industries ranging from energy to chemicals and food processing.

GX Plates

The GX series is engineered for asymmetrical flow applications. These plates feature an additional peripheral gasket that enhances sealing performance and minimizes leakage risk. Each plate also includes dual O-ring seals across alternate openings, creating a reliable flow separation system.

Chevron patterns vary across the series to serve different performance goals:

GC Plates

The GC model is part of the GCP series and is tailored for systems with low flow requirements. Featuring a standard chevron design, these plates support a consistent, parallel flow—ideal for smaller or more precise applications.

GFP Plates

Designed to resist fouling and extend service intervals, GFP plates are durable and ideal for challenging environments such as sugar plants, alcohol distilleries, textile factories, paper mills, and the chemical industry.

They are typically paired with seals made of NBR or EPDM, depending on the media and operating temperature.

GD Plates

GD or “double plates” are precision-built to eliminate any risk of cross-contamination. A leak, if it occurs, will remain visible without mixing the two media—an essential feature in sensitive applications like pharmaceuticals or food processing.

PHEwtur produces high-quality compatible gaskets for Tranter plate heat exchangers, offering the same technical standards as OEM gaskets but at a more attractive price point.

Choosing a gasket starts with choosing the right raw material. At PHEwtur, only European-sourced elastomers are used, ensuring consistency and durability. It’s not just about the label—performance lies in the quality of the base materials.

As a recognized global expert in elastomer gasket manufacturing, PHEwtur provides a broad range of seals that mirror Tranter’s specifications, fully compliant with international quality benchmarks.

All PHEwtur gaskets are subject to rigorous testing by experienced technical teams.

Interested in learning more? Contact us and let’s talk about the right gasket for your system.