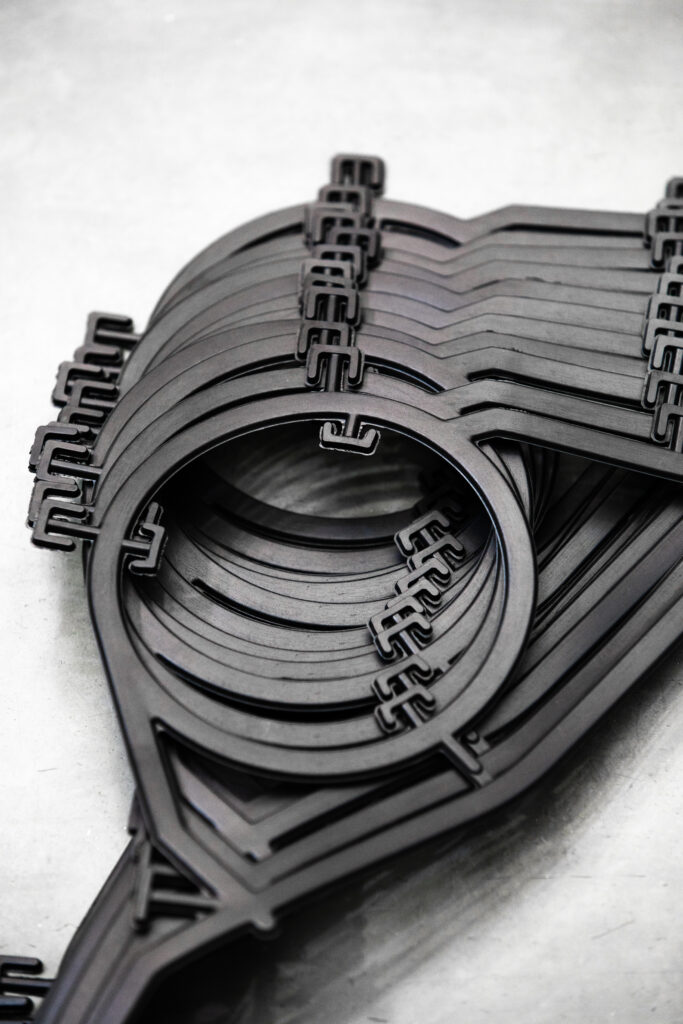

PHEwtur offers one of the wide range of equivalent gaskets for Sondex plate heat exchangers.

S4A

S7A

S8

S8A

S9A

S14A

S15

S19

S20

S20A

S21A

S30

S38

S39

S43

S50

S60

S61

S65

S72

S100

S120

S130

S152

S152 CLIP-GLUE

S21 SONDERLOCK

S22 SONDERLOCK

S35 SONDERSNAP

S37 SONDERLOCK

S41 SONDERLOCK

S43 SONDERLOCK

S47 SONDERLOCK

S62 SONDERLOCK

S64 SONDERLOCK

S65 SONDERLOCK

S86 SONDERLOCK

S100 SONDERLOCK

S110 SONDERLOCK

S121 SONDERLOCK

S130 SONDERLOCK

S188 SONDERLOCK

SF53

SF229

SF131

SFD13

SFD13 NEWDESIGN

SFD22

SFD35

Sondex was founded in 1984 in Aarhus, Denmark, by Aage Søndergaard Nielsen. From the beginning, the company specialized in designing and manufacturing plate heat exchangers, focusing on customized solutions for industries such as district heating, food and beverage, marine, and industrial processing.

Sondex quickly gained a strong reputation for innovation and high-quality engineering, leading to rapid global expansion. Over the years, the product range was significantly broadened to include brazed, welded, and spiral heat exchangers, as well as freshwater distillers and district heating units. This growth positioned Sondex as a key global player in the heat transfer solutions market, with around 40 subsidiaries and manufacturing facilities worldwide.

In July 2016, Sondex was fully acquired by Danfoss, another Danish company renowned for its expertise in heating and cooling solutions. This acquisition allowed Danfoss to strengthen its position in the heat transfer market by combining its technologies with Sondex’s extensive product line and technical know-how.

Today, SONDEX products are part of the Danfoss portfolio, continuing to deliver innovative, energy-efficient heat exchanger solutions. The legacy of Sondex lives on through Danfoss’s commitment to quality, customization, and customer satisfaction across global industries.

SONDEX offers a wide range of plate heat exchangers designed to meet the needs of various industrial applications. These include:

Brazed Plate Heat Exchangers

Designed for applications involving high temperatures and pressures, brazed plate heat exchangers offer efficient heat transfer in a compact footprint. The plates are permanently brazed together, eliminating the need for gaskets and allowing for high-performance thermal efficiency.

Welded Plate Heat Exchangers

Suitable for demanding environments, welded plate heat exchangers are built to handle aggressive media and extreme operating conditions. The plates are welded together to ensure high mechanical strength and resistance to pressure and temperature.

Gasketed Plate Heat Exchangers

Ideal for applications with moderate temperatures and pressures, these exchangers use replaceable gaskets between the plates, allowing for easy maintenance and cleaning. They provide excellent thermal performance and flexibility in a wide range of industries.

At PHEwtur, we specialize in providing high-quality replacement gaskets for plate heat exchangers. Our products offer exceptional performance at competitive prices, meeting the needs of even the most demanding industrial users.

We understand that gaskets are critical to the efficiency and sealing integrity of a plate heat exchanger. That’s why we offer a wide selection of compatible gaskets for major brands, including SONDEX®, Alfa Laval, Tranter, APV, and many more.

Our gaskets are manufactured to strict quality standards, ensuring performance equal to or better than original parts. We use top-grade materials such as Nitrile (NBR), EPDM, Silicone, and FKM (Viton), which provide excellent resistance to wear, chemicals, and high temperatures.

Contact us now to have more information about our products